High pressure horizontal slurry pump for mining

Product Description

High pressure horizontal slurry pump for mining

Introduction:

SME SBH series pumps are severe duty, high head slurry pumps, fit for a variety of applications ranging from filter press feeds to pipeline transport staging pumps. The high heads along with sturdier wear parts makes these pumps some of the most rugged in the SME slurry pump line. Extensive exterior ribbing allows for higher heads to be reached with a single pump, and bulked up wet end parts handle the toughest applications in the field today.

At SME, satisfaction is guaranteed. We have time and again delivered the best quality and service when it comes to maintaining SME slurry pumps in mines, mills and prep plants around the world. Plate and frame filter presses are becoming more and more commonplace in fines recovery applications at coal preparation and mining operations around the world with the steady elimination of settling or tailings ponds. These presses carry a relatively high capital cost, but the payoff is in the long term savings on chemicals and pond management. The heart of the these filter presses is the centrifugal pump that fills the press, and subsequently aids in the hydraulic pressing of the material.

A brief introduction of the slurry pumps we offer:

Slurry Pump Series:

1. Metal Lined Slurry Pump, SH Type; 2. Rubber Lined Slurry Pump (SHR Type); 3. Hi-Pressure Slurry Pump (SBH Type);

Gravel Pump Series:

1. Hard Metal Sand Pump (SG, SHG Type); 2. WN Dredging Pump (WN Type);

Sump Pump Series:

1. Metal Vertical Slurry Pump (SV Type); 2. Rubber Vertical Slurry Pump (SVR Type);

Local Pump Series:

1. Power Plant Slurry Pump (ZBG Type); 2. Coal Washing Slurry Pump (ZJ Type);

Froth Pump Series

Features:

1. High effektifnost, wear resistance, stable performance, replaceable parts, high pressure, saving energy.

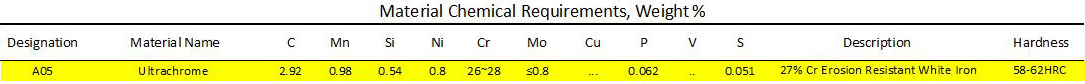

2. The main wear parts shlamvyh pumps, that is, that is, the components of the flow part: the impeller, lining cap liner pump casing liner to the front, rear bronedisk.Obychno they are made of wear-resistant metal materials razvidyh, naprimerA05, A49, and other high-chromium alloy, or elastomera.Nesuschy layer and the wear layer can be separated.

3. High-efficiency impeller large diameter, its large internal channels reduces the flow rate uvlichivaya equipment life and reducing operating costs.

4. Due to the cylindrical structure of the bearing assembly is very convenient to adjust the clearance between the impeller and the front bronediskom.Mezhdu in the bearing assembly can be completely disassembled for maintenance or lubrication detaley.Podshipniki lubricated with lubricating oil.

5. We have different types of shaft seals, including packing, mechanical seal, expeller seal and seal expeller with fillers.

6. Depending on the actual requirements of the outlet may be located at any of positions angularly 8mm interavalom 45 degrees.

7. The pumps can be serially connected to achieve high pressure.

8. Transmission Type: Direct Drive ((DC), belt drive (CR, CV, ZV, CL) pulsatile

Application of high-pressure slurry pumps SBH:

- Pumping tailings

- Power supply and transport of materials

- Concentration of ore metallurgy

- Industrial processing of salt and sugar

- Removal of slag and dust power

- Processing of mineral substances

Specifications:

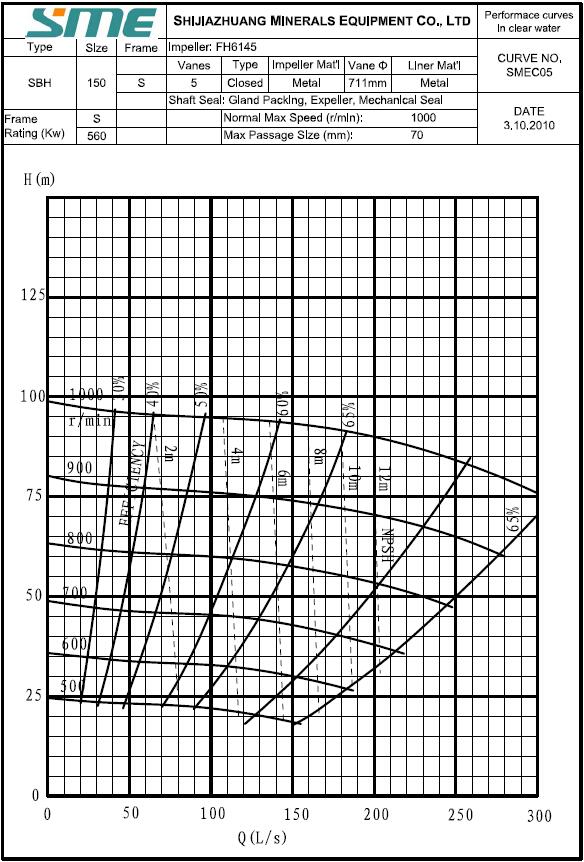

| Model | SBH-150S |

| Outlet | 6-inch |

| Capacity | 468-1008m3/h |

| TDH | 20-94m |

| Rated Motor Power | 560Kw |

| Speed | 500-1000r/min |

| NPSH | 4-12m |

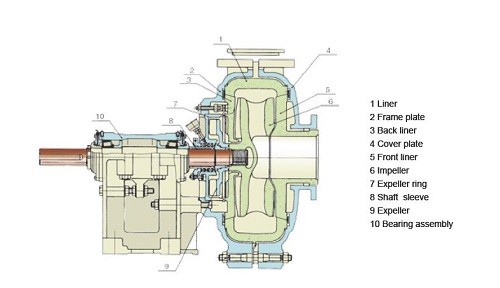

Construction of Metal Slurry Pump:

Standard Material of Wet-end Parts: Hi-Chrome Alloy A05

Performance Curve:

Projects with SME Slurry Pumps:

Product Categories : Slurry Pump > Hi-Pressure Slurry Pump