NBR/FKM Tb/BS Type Outer Skeleton Double Lips Oil Seal

Basic Info

Model No.: TB series

Product Description

Model NO.: TB series Usage: Shaft Sealing, Motors, Pumps,Transmissions Speed: High Speed Lip: Lips Type Color: Customized Roughness Ra: 0.2-0.8 M Hardness: 45-60 HRC FKM Thermal Application: -15~+200 Celicus Degree Reciprocation Speed: 0-20m/S Trademark: morgan Origin: China Material: NBR, FKM, EPDM or Customized Type: Assembled Pressure: Atmospheric Type Standard: Standard Shaft Tolerance: ISO H 11 Roughness Rz: 1.0-5.0 M NBR Thermal Application: -30~+100 Celicus Degree Pressure Data: 0-0.05MPa Non-Standard: Accept Customized Products Specification: 6-1820mm HS Code: 4016931000 Description

The TB profile Oil Seals is a shaft seal composed of a single external metal cage with an internal rubber coating, a primary sealing lip with integrated spring and an additional anti-pollution sealing lip.

Advantages

Good radial rigidity, particularly for large diameters

Good stability when assembled, preventing the bounce-back effect

Sealing for low and high viscosity fluids

Modern primary sealing lip with low radial forces

Protection against undesirable air contaminantsApplications Shaft sealing

Motors

Pumps

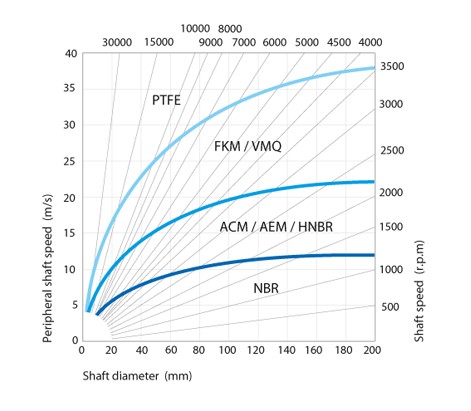

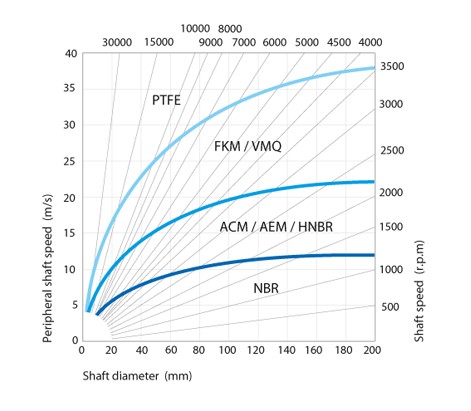

TransmissionsSpeed The table below indicates the relationships between the linear speed, the rotation speed and the recommended material.

The shaft seals with an additional protective lip are limited to a speed of 8 m/s.

Linear speed calculation:

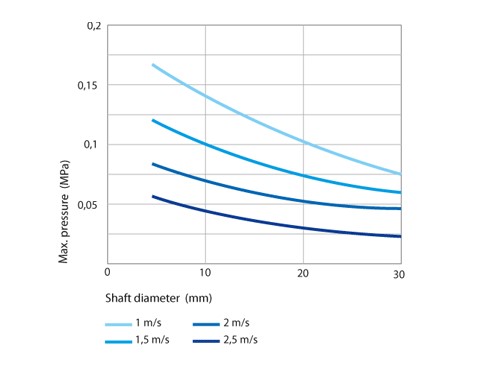

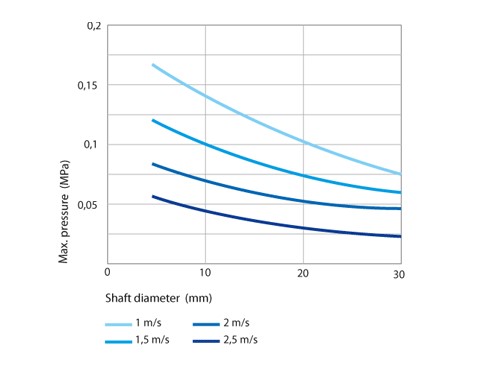

s (m/s) = [Ø shaft (mm) x speed (rpm) x π] / 60,000Pressure The standard shaft seals are generally used in unpressurised environments, or for pressures between 0.02 and 0.05 MPa maximum.

Higher pressures are acceptable, following testing, for standard NBR or FKM shaft seals used on a shaft diameter less than 30 mm. Refer to the graph below: Temperature The table below indicates the temperature limits, depending on the materials and fluids used.

Temperature The table below indicates the temperature limits, depending on the materials and fluids used.

The sealing lip of the shaft seal endures a higher temperature due to shaft rotation, and the significant pressure and friction on the mechanical parts. Good lubrication is therefore necessary to allow for a better release of heat and thus limits the temperature rise in the parts subjected to friction.

By definition, the temperature at the edge of the seal is raised when the rotation speed (and thus the linear speed) as well as the shaft diameter increases. Fluids Mineral oils In general, this type of oil has few additives and is therefore perfectly suitable for all of the rubbers used for the rotary shaft seals. The following oils are suitable for rotating applications: motor oils gearbox oils hypoid oils ATF oils for automatic gearboxes transmission oils synthetic oils This type of oil is used to improve different characteristics such as the resistance to ageing, resistance to high temperatures, viscosity, etc. and has a good compatibility with the majority of rubbers used for the shaft seals. Tests may need to be performed beforehand to measure the degree of compatibility of this type of oil with the materials used. Among the synthetic oils are: brake fluids fluids for automatic gearboxes fluids for suspensions fluids for steering systems fluids for hydraulic transmissions Hypoid oils This type of oil contains special components such as EP additives. These enable lubrication and thus limit any seizing at the bearings, for example. When affected by heat, these additives have the tendency to lead to deposits on the sealing lip. That is why we recommend using shaft seals with a sealing lip comprising return pumping leads in order to limit the increase in temperature and above all, to reduce these potential carbon deposits.Greases Greases are generally applied to bearings etc. and require specific adaptation to provide favourable operating conditions for the shaft seal. To prevent the lip of the seal from sustaining more significant pressures than planned, we recommend positioning the lip seal on one side of the bearing in such a way so that the lip is not prematurely destroyed. We also recommend reducing the rotation speed by 50% when lubricated, to ensure that less heat escapes during friction.Aggressive fluids It is critical to choose the correct material to better resist different aggressive fluids (acids, solvents, chemical products, etc.). For applications in a rotating environment, we recommend using materials such as FKM rather than NBR. For operations that are dry or use very little lubrication, and where the rubbers do not resist certain aggressive fluids, we advise you to use our PTFE shaft seals.SEAL DESIGN Tolerance for the outside diameter of the seal (ØD) The table below indicates the pre-tightening for shaft seals on the housing diameter according to standard ISO 6194-1.

Tolerance for the inside diameter of the seal (Ød) Free and without constraint, the inside diameter of the sealing lip is always smaller than the diameter of the shaft. The pre-tightening or interference denotes the difference between these two values. Depending on the shaft diameter, the diameter of the sealing lip is generally considered to be less, between 0.8 and 3.5 mm.SHAFT DESIGN Shaft material

Suitable materials are: ordinary C35 and C45 steels used in mechanical construction 1.4300 and 1.4112 stainless steels for sealing water sprayed carbide coatings graphite malleable cast iron materials with a CVD and PVD coating Not appropriate: chrome coatings solidified through non-uniform wear plastic materials resulting from low thermal conductivity, which can lead to a disturbance in the transport of heat, an increase in temperature in friction areas with the shaft seal, as well as a potential softening Shaft hardness

Shaft hardness will depend on the linear speed (in m/s) and the level of pollution.

Surface roughness

The recommendations below must be considered for the quality of the shaft surface area.

Standard conditions: Ra = 0.2 to 0.8 µm and 0.1 for demanding applications Rz = 1.0 to 4.0 µm Rmax ≤ 6.3 µm For pressurev > 0.1 MPa: Ra = 0.2 to 0.4 µm and 0.1 for demanding applications Rz = 1.0 to 3.0 µm Rmax ≤ 6.3 µm Shaft tolerance

The shaft must have a tolerance of h11, in line with standard ISO 286-2

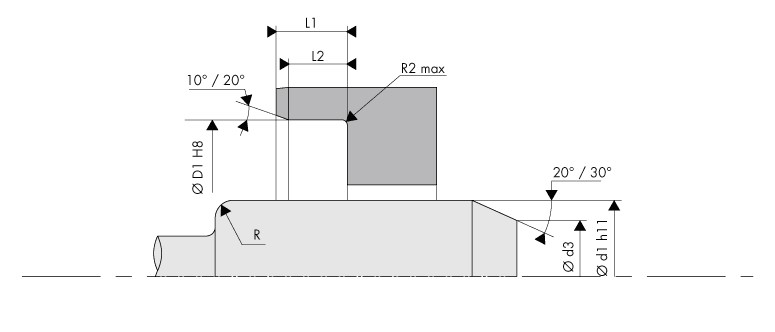

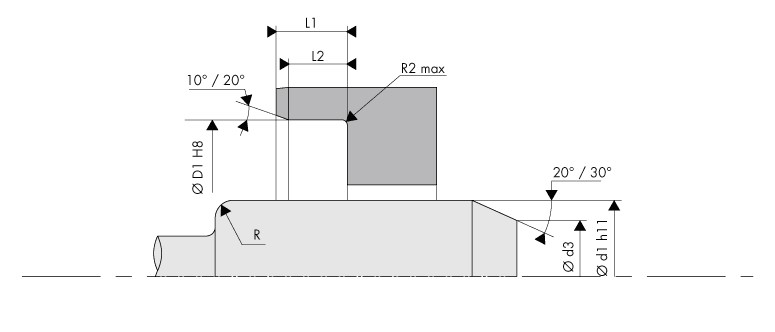

Chamfer and radius

You are strongly advised to install a chamfer on the shaft so as not to alter the primary sealing sealing lip of the shaft seal during assembly. Please refer to the table below.

Note: For non-standard dimension Oil Seal, morgan seal is able to produce them. Please do not hesitate to contact with us.

Morgan Seals has the biggest vulcanizing machine(4000T) and different kinds of seal moulds. So for the non standard Oil seals, please do not hesitate to contact with us. The following is the the picture of our moulds.

Our services:

Guangzhou Morgan Seals Co., Ltd the expert in sealing solution field who combines the rich seals research and production experience of her parent firm with the advanced technology and administration of Morgan, Worcester. Morgan Seals Research and Development ability is based on her parent firm who has won awards as scientific research achievements for more than 1000 projects and over 200 of them won scientific and technological progress prizes of municipal, provincial, ministerial and national levels. At the same time, it also has one National Certified Laboratory, one National Engineering Research Centers and three Industry Level Inspection Centers.

Contact us if you need more details on Oil Seal. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Skeleton Oil Seal、Double Lips Oil Seal. If these products fail to match your need, please contact us and we would like to provide relevant information.

The TB profile Oil Seals is a shaft seal composed of a single external metal cage with an internal rubber coating, a primary sealing lip with integrated spring and an additional anti-pollution sealing lip.

Advantages

Good radial rigidity, particularly for large diameters

Good stability when assembled, preventing the bounce-back effect

Sealing for low and high viscosity fluids

Modern primary sealing lip with low radial forces

Protection against undesirable air contaminantsApplications Shaft sealing

Motors

Pumps

TransmissionsSpeed The table below indicates the relationships between the linear speed, the rotation speed and the recommended material.

The shaft seals with an additional protective lip are limited to a speed of 8 m/s.

Linear speed calculation:

s (m/s) = [Ø shaft (mm) x speed (rpm) x π] / 60,000Pressure The standard shaft seals are generally used in unpressurised environments, or for pressures between 0.02 and 0.05 MPa maximum.

Higher pressures are acceptable, following testing, for standard NBR or FKM shaft seals used on a shaft diameter less than 30 mm. Refer to the graph below:

Temperature The table below indicates the temperature limits, depending on the materials and fluids used.

Temperature The table below indicates the temperature limits, depending on the materials and fluids used.| Media | Maximum temperature, depending on the materials | |||||||

| ACM | AEM | EPDM | FKM | HNBR | NBR | VMQ | ||

| Mineral oils | Oils for motors | +130°C | +130°C | - | +170°C | +130°C | +100°C | +150°C |

| Oils for gearboxes | +120°C | +130°C | - | +150°C | +110°C | +80°C | +130°C | |

| Oils for hypoid gears | +120°C | +130°C | - | +150°C | +110°C | +80°C | - | |

| ATF oils | +120°C | +130°C | - | +170°C | +130°C | +100°C | - | |

| Hydraulic oils | +120°C | +130°C | +150°C | +130°C | +90°C | - | ||

| Greases | - | +130°C | - | - | +100°C | +90°C | - | |

| Fire-resistant fluids | HFA group - Emulsion with more than 80% water | - | - | - | - | +70°C | +70°C | +60°C |

| HFB group - Opposite solution (water in oil) | - | - | - | - | +70°C | +70°C | +60°C | |

| HFC group - Polymer aqueous solution | - | - | +60°C | - | +70°C | +70°C | - | |

| HFD group - Water-free synthetic fluids | - | - | - | +150°C | - | - | - | |

| Other fluids | EL + L heating oil | - | - | - | - | +100°C | +90°C | - |

| Air | +150°C | +150°C | +150°C | +200°C | +130°C | +90°C | +200°C | |

| Water | - | - | +150°C | +100°C | +100°C | +90°C | - | |

| Water for washing | - | - | +130°C | +100°C | +100°C | +100°C | - | |

| Temperature range | Min. | -25°C | -40°C | -45°C | -20°C | -30°C | -30°C | -60°C |

| Max. | +150°C | +150°C | +150°C | +200°C | +150°C | +100°C | +200°C | |

By definition, the temperature at the edge of the seal is raised when the rotation speed (and thus the linear speed) as well as the shaft diameter increases. Fluids Mineral oils In general, this type of oil has few additives and is therefore perfectly suitable for all of the rubbers used for the rotary shaft seals. The following oils are suitable for rotating applications: motor oils gearbox oils hypoid oils ATF oils for automatic gearboxes transmission oils synthetic oils This type of oil is used to improve different characteristics such as the resistance to ageing, resistance to high temperatures, viscosity, etc. and has a good compatibility with the majority of rubbers used for the shaft seals. Tests may need to be performed beforehand to measure the degree of compatibility of this type of oil with the materials used. Among the synthetic oils are: brake fluids fluids for automatic gearboxes fluids for suspensions fluids for steering systems fluids for hydraulic transmissions Hypoid oils This type of oil contains special components such as EP additives. These enable lubrication and thus limit any seizing at the bearings, for example. When affected by heat, these additives have the tendency to lead to deposits on the sealing lip. That is why we recommend using shaft seals with a sealing lip comprising return pumping leads in order to limit the increase in temperature and above all, to reduce these potential carbon deposits.Greases Greases are generally applied to bearings etc. and require specific adaptation to provide favourable operating conditions for the shaft seal. To prevent the lip of the seal from sustaining more significant pressures than planned, we recommend positioning the lip seal on one side of the bearing in such a way so that the lip is not prematurely destroyed. We also recommend reducing the rotation speed by 50% when lubricated, to ensure that less heat escapes during friction.Aggressive fluids It is critical to choose the correct material to better resist different aggressive fluids (acids, solvents, chemical products, etc.). For applications in a rotating environment, we recommend using materials such as FKM rather than NBR. For operations that are dry or use very little lubrication, and where the rubbers do not resist certain aggressive fluids, we advise you to use our PTFE shaft seals.SEAL DESIGN Tolerance for the outside diameter of the seal (ØD) The table below indicates the pre-tightening for shaft seals on the housing diameter according to standard ISO 6194-1.

| Bore diameter ØD1 (mm) | Tolerances on the outside diameter ØD of the ring | Roundness tolerance | |||

| Apparent metal cage | Rubber coating | Coating with grooves | Apparent metal cage | Rubber coating | |

| ØD1 ≤ 50.0 | +0.10 / +0.20 | +0.15 / +0.30 | +0.20 / +0.40 | 0.18 | 0.25 |

| 50.0 < ØD1 ≤ 80.0 | +0.13 / +0.23 | +0.20 / +0.35 | +0.25 / +0.45 | 0.25 | 0.35 |

| 80.0 < ØD1 ≤ 120.0 | +0.15 / +0.25 | +0.20 / +0.35 | +0.25 / +0.45 | 0.30 | 0.50 |

| 120.0 < ØD1 ≤ 180.0 | +0.18 / +0.28 | +0.25 / +0.45 | +0.30 / +0.55 | 0.40 | 0.65 |

| 180.0 < ØD1 ≤ 300.0 | +0.20 / +0.30 | +0.25 / +0.45 | +0.30 / +0.55 | 0.25% of ØD | 0.80 |

| 300.0 < ØD1 ≤ 500.0 | +0.23 / +0.35 | +0.30 / +0.55 | +0.35 / +0.65 | 0.25% of ØD | 1.00 |

| 500.0 < ØD1 ≤ 630.0 | +0.23 / +0.35 | +0.35 / +0.65 | +0.40 / +0.75 | - | - |

| 630.0 < ØD1 ≤ 800.0 | +0.28 / +0.43 | +0.40 / +0.75 | +0.45 / +0.85 | - | - |

Suitable materials are: ordinary C35 and C45 steels used in mechanical construction 1.4300 and 1.4112 stainless steels for sealing water sprayed carbide coatings graphite malleable cast iron materials with a CVD and PVD coating Not appropriate: chrome coatings solidified through non-uniform wear plastic materials resulting from low thermal conductivity, which can lead to a disturbance in the transport of heat, an increase in temperature in friction areas with the shaft seal, as well as a potential softening Shaft hardness

Shaft hardness will depend on the linear speed (in m/s) and the level of pollution.

| Rotation speed | Hardness in HRC |

|---|---|

| s ≤ 4.0 m/s | 45 HRC |

| 4.0 < s ≤ 10.0 m/s | 55 HRC |

| s > 10.0 m/s | 60 HRC |

The recommendations below must be considered for the quality of the shaft surface area.

Standard conditions: Ra = 0.2 to 0.8 µm and 0.1 for demanding applications Rz = 1.0 to 4.0 µm Rmax ≤ 6.3 µm For pressurev > 0.1 MPa: Ra = 0.2 to 0.4 µm and 0.1 for demanding applications Rz = 1.0 to 3.0 µm Rmax ≤ 6.3 µm Shaft tolerance

The shaft must have a tolerance of h11, in line with standard ISO 286-2

| Shaft diameter Ød1 (mm) | Tolerance h11 (mm) |

|---|---|

| Ød1 ≤ 3.0 | -0.060 / 0 |

| 3.0 < Ød1 ≤ 6.0 | -0.075 / 0 |

| 6.0 < Ød1 ≤ 10.0 | -0.090 / 0 |

| 10.0 < Ød1 ≤ 18.0 | -0.110 / 0 |

| 18.0 < Ød1 ≤ 30.0 | -0.130 / 0 |

| 30.0 < Ød1 ≤ 50.0 | -0.160 / 0 |

| 50.0 < Ød1 ≤ 80.0 | -0.190 / 0 |

| 80.0 < Ød1 ≤ 120.0 | -0.220 / 0 |

| 120.0 < Ød1 ≤ 180.0 | -0.250 / 0 |

| 180.0 < Ød1 ≤ 250.0 | -0.290 / 0 |

| 250.0 < Ød1 ≤ 315.0 | -0.320 / 0 |

| 315.0 < Ød1 ≤ 400.0 | -0.360 / 0 |

| 400.0 < Ød1 ≤ 500.0 | -0.400 / 0 |

You are strongly advised to install a chamfer on the shaft so as not to alter the primary sealing sealing lip of the shaft seal during assembly. Please refer to the table below.

| Shaft diameter Ød1 (mm) | Chamfer diameter Ød3 (mm) | Radius R (mm) |

|---|---|---|

| Ød1 ≤ 10.0 | Ød1 - 1.50 | 2.00 |

| 10.0 < Ød1 ≤ 20.0 | Ød1 - 2.00 | 2.00 |

| 20.0 < Ød1 ≤ 30.0 | Ød1 - 2.50 | 3.00 |

| 30.0 < Ød1 ≤ 40.0 | Ød1 - 3.00 | 3.00 |

| 40.0 < Ød1 ≤ 50.0 | Ød1 - 3.50 | 4.00 |

| 50.0 < Ød1 ≤ 70.0 | Ød1 - 4.00 | 4.00 |

| 70.0 < Ød1 ≤ 95.0 | Ød1 - 4.50 | 5.00 |

| 95.0 < Ød1 ≤ 130.0 | Ød1 - 5.50 | 6.00 |

| 130.0 < Ød1 ≤ 240.0 | Ød1 - 7.00 | 8.00 |

| 240.0 < Ød1 ≤ 500.0 | Ød1 - 11.00 | 12.00 |

| shaft diameter | OD | Width | circularity tolerance | |||

| d1/mm | D/mm | ES/mm | EI/mm | b/mm | Limit deviation/mm | δ/mm |

| 6 | 16 | 0.08 | -0.3 | 7 | ±0.3 | 0.18 |

| 6 | 22 | 0.08 | -0.3 | 7 | ±0.3 | 0.18 |

| 7 | 22 | 0.08 | -0.3 | 7 | ±0.3 | 0.18 |

| 8 | 22 | 0.08 | -0.3 | 7 | ±0.3 | 0.18 |

| 8 | 24 | 0.08 | -0.3 | 7 | ±0.3 | 0.18 |

| 9 | 22 | 0.08 | -0.3 | 7 | ±0.3 | 0.18 |

| 10 | 22 | 0.08 | -0.3 | 7 | ±0.3 | 0.18 |

| 10 | 25 | 0.08 | -0.3 | 7 | ±0.3 | 0.18 |

| 12 | 24 | 0.08 | -0.3 | 7 | ±0.3 | 0.18 |

| 12 | 25 | 0.08 | -0.3 | 7 | ±0.3 | 0.18 |

| 12 | 30 | 0.08 | -0.3 | 7 | ±0.3 | 0.18 |

| 15 | 26 | 0.08 | -0.3 | 7 | ±0.3 | 0.18 |

| 15 | 30 | 0.08 | -0.3 | 7 | ±0.3 | 0.18 |

| 15 | 35 | 0.08 | -0.3 | 7 | ±0.3 | 0.18 |

| 16 | 28 | 0.08 | -0.3 | 7 | ±0.3 | 0.18 |

| 16 | 30 | 0.08 | -0.3 | 7 | ±0.3 | 0.18 |

| 16 | 35 | 0.23 | -0.09 | 7 | ±0.3 | 0.26 |

| 18 | 30 | 0.2 | -0.08 | 7 | ±0.3 | 0.18 |

| 18 | 35 | 0.08 | -0.3 | 7 | ±0.3 | 0.18 |

| 18 | 40 | 0.08 | -0.3 | 7 | ±0.3 | 0.18 |

| 20 | 35 | 0.08 | -0.3 | 7 | ±0.3 | 0.18 |

| 20 | 40 | 0.08 | -0.3 | 7 | ±0.3 | 0.18 |

| 20 | 45 | 0.08 | -0.3 | 7 | ±0.3 | 0.18 |

| 22 | 35 | 0.08 | -0.3 | 7 | ±0.3 | 0.18 |

| 22 | 40 | 0.08 | -0.3 | 7 | ±0.3 | 0.18 |

| 22 | 47 | 0.08 | -0.3 | 7 | ±0.3 | 0.18 |

| 25 | 40 | 0.08 | -0.3 | 7 | ±0.3 | 0.18 |

| 25 | 47 | 0.08 | -0.3 | 7 | ±0.3 | 0.18 |

| 25 | 52 | 0.23 | -0.09 | 7 | ±0.3 | 0.26 |

| 28 | 40 | 0.2 | -0.08 | 7 | ±0.3 | 0.18 |

| 28 | 47 | 0.2 | -0.08 | 7 | ±0.3 | 0.18 |

| 28 | 52 | 0.23 | -0.09 | 7 | ±0.3 | 0.26 |

| 30 | 42 | 0.2 | -0.08 | 7 | ±0.3 | 0.18 |

| 30 | 47 | 0.2 | -0.08 | 7 | ±0.3 | 0.18 |

| 30 | 50 | 0.2 | -0.08 | 7 | ±0.3 | 0.18 |

| 30 | 52 | 0.23 | -0.09 | 7 | ±0.3 | 0.26 |

| 32 | 45 | 0.2 | -0.08 | 8 | ±0.3 | 0.18 |

| 32 | 47 | 0.2 | -0.08 | 8 | ±0.3 | 0.18 |

| 32 | 52 | 0.23 | -0.09 | 8 | ±0.3 | 0.26 |

| 35 | 50 | 0.2 | -0.08 | 8 | ±0.3 | 0.18 |

| 35 | 52 | 0.23 | -0.09 | 8 | ±0.3 | 0.26 |

| 35 | 55 | 0.23 | -0.09 | 8 | ±0.3 | 0.26 |

| 38 | 55 | 0.23 | -0.09 | 8 | ±0.3 | 0.26 |

| 38 | 58 | 0.23 | -0.09 | 8 | ±0.3 | 0.26 |

| 38 | 62 | 0.23 | -0.09 | 8 | ±0.3 | 0.26 |

| 40 | 55 | 0.23 | -0.09 | 8 | ±0.3 | 0.26 |

| 40 | 60 | 0.23 | -0.09 | 8 | ±0.3 | 0.26 |

| 40 | 62 | 0.23 | -0.09 | 8 | ±0.3 | 0.26 |

| 42 | 55 | 0.23 | -0.09 | 8 | ±0.3 | 0.26 |

| 42 | 62 | 0.23 | -0.09 | 8 | ±0.3 | 0.26 |

| 42 | 65 | 0.23 | -0.09 | 8 | ±0.3 | 0.26 |

| 45 | 62 | 0.23 | -0.09 | 8 | ±0.3 | 0.26 |

| 45 | 65 | 0.23 | -0.09 | 8 | ±0.3 | 0.26 |

| 45 | 70 | 0.23 | -0.09 | 8 | ±0.3 | 0.26 |

| 50 | 68 | 0.23 | -0.09 | 8 | ±0.3 | 0.26 |

| 50 | 70 | 0.23 | -0.09 | 8 | ±0.3 | 0.26 |

| 50 | 72 | 0.23 | -0.09 | 8 | ±0.3 | 0.26 |

| 52 | 72 | 0.23 | -0.09 | 8 | ±0.3 | 0.26 |

| 52 | 75 | 0.23 | -0.09 | 8 | ±0.3 | 0.26 |

| 52 | 80 | 0.23 | -0.09 | 8 | ±0.3 | 0.26 |

| 55 | 72 | 0.23 | -0.09 | 8 | ±0.3 | 0.26 |

| 55 | 75 | 0.23 | -0.09 | 8 | ±0.3 | 0.26 |

| 55 | 80 | 0.23 | -0.09 | 8 | ±0.3 | 0.26 |

| 60 | 80 | 0.23 | -0.09 | 8 | ±0.3 | 0.26 |

| 60 | 85 | 0.1 | -0.25 | 8 | ±0.3 | 0.3 |

| 60 | 90 | 0.1 | -0.25 | 8 | ±0.3 | 0.3 |

| 65 | 85 | 0.1 | -0.25 | 10 | ±0.3 | 0.3 |

| 65 | 90 | 0.1 | -0.25 | 10 | ±0.3 | 0.3 |

| 65 | 95 | 0.1 | -0.25 | 10 | ±0.3 | 0.3 |

| 70 | 90 | 0.1 | -0.25 | 10 | ±0.3 | 0.3 |

| 70 | 95 | 0.1 | -0.25 | 10 | ±0.3 | 0.3 |

| 70 | 100 | 0.1 | -0.25 | 10 | ±0.3 | 0.3 |

| 75 | 95 | 0.1 | -0.25 | 10 | ±0.3 | 0.3 |

| 75 | 100 | 0.1 | -0.25 | 10 | ±0.3 | 0.3 |

| 80 | 100 | 0.1 | -0.25 | 10 | ±0.3 | 0.3 |

| 80 | 105 | 0.1 | -0.25 | 10 | ±0.3 | 0.3 |

| 80 | 110 | 0.1 | -0.25 | 10 | ±0.3 | 0.3 |

| 85 | 105 | 0.1 | -0.25 | 12 | ±0.4 | 0.3 |

| 85 | 110 | 0.1 | -0.25 | 12 | ±0.4 | 0.3 |

| 85 | 120 | 0.1 | -0.25 | 12 | ±0.4 | 0.3 |

| 90 | 110 | 0.1 | -0.25 | 12 | ±0.4 | 0.3 |

| 90 | 115 | 0.1 | -0.25 | 12 | ±0.4 | 0.3 |

| 90 | 120 | 0.1 | -0.25 | 12 | ±0.4 | 0.3 |

| 95 | 120 | 0.1 | -0.25 | 12 | ±0.4 | 0.3 |

| 95 | 125 | 0.12 | -0.28 | 12 | ±0.4 | 0.4 |

| 95 | 130 | 0.12 | -0.28 | 12 | ±0.4 | 0.4 |

| 100 | 125 | 0.12 | -0.28 | 12 | ±0.4 | 0.4 |

| 100 | 130 | 0.12 | -0.28 | 12 | ±0.4 | 0.4 |

| 100 | 140 | 0.12 | -0.28 | 12 | ±0.4 | 0.4 |

| 105 | 130 | 0.12 | -0.28 | 12 | ±0.4 | 0.4 |

| 105 | 140 | 0.12 | -0.28 | 12 | ±0.4 | 0.4 |

| 110 | 140 | 0.12 | -0.28 | 12 | ±0.4 | 0.4 |

| 110 | 150 | 0.12 | -0.28 | 12 | ±0.4 | 0.4 |

| 115 | 140 | 0.12 | -0.28 | 12 | ±0.4 | 0.4 |

| 115 | 150 | 0.12 | -0.28 | 12 | ±0.4 | 0.4 |

| 120 | 150 | 0.12 | -0.28 | 12 | ±0.4 | 0.4 |

| 120 | 160 | 0.12 | -0.28 | 12 | ±0.4 | 0.4 |

| 125 | 150 | 0.12 | -0.28 | 12 | ±0.4 | 0.4 |

| 130 | 160 | 0.12 | -0.28 | 12 | ±0.4 | 0.4 |

| 130 | 170 | 0.12 | -0.28 | 12 | ±0.4 | 0.4 |

| 140 | 170 | 0.12 | -0.28 | 15 | ±0.4 | 0.4 |

| 140 | 180 | 0.12 | -0.28 | 15 | ±0.4 | 0.4 |

| 150 | 180 | 0.12 | -0.28 | 15 | ±0.4 | 0.4 |

| 150 | 190 | 0.15 | -0.35 | 15 | ±0.4 | 0.475 |

| 160 | 190 | 0.15 | -0.35 | 15 | ±0.4 | 0.475 |

| 160 | 200 | 0.15 | -0.35 | 15 | ±0.4 | 0.5 |

| 170 | 200 | 0.15 | -0.35 | 15 | ±0.4 | 0.5 |

| 180 | 210 | 0.15 | -0.35 | 15 | ±0.4 | 0.525 |

| 190 | 220 | 0.15 | -0.35 | 15 | ±0.4 | 0.55 |

| 200 | 230 | 0.15 | -0.35 | 15 | ±0.4 | 0.575 |

| 220 | 250 | 0.15 | -0.35 | 15 | ±0.4 | 0.625 |

| 240 | 270 | 0.15 | -0.35 | 15 | ±0.4 | 0.675 |

| 250 | 290 | 0.15 | -0.35 | 15 | ±0.4 | 0.725 |

| 260 | 300 | 0.15 | -0.35 | 20 | ±0.4 | 0.75 |

| 280 | 320 | 0.2 | -0.45 | 20 | ±0.4 | 0.8 |

| 300 | 340 | 0.2 | -0.45 | 20 | ±0.4 | 0.85 |

| 320 | 360 | 0.2 | -0.45 | 20 | ±0.4 | 0.9 |

| 340 | 380 | 0.2 | -0.45 | 20 | ±0.4 | 0.95 |

| 360 | 400 | 0.2 | -0.45 | 20 | ±0.4 | 1 |

| 380 | 420 | 0.2 | -0.45 | 20 | ±0.4 | 1.05 |

| 400 | 440 | 0.2 | -0.45 | 20 | ±0.4 | 1.1 |

Morgan Seals has the biggest vulcanizing machine(4000T) and different kinds of seal moulds. So for the non standard Oil seals, please do not hesitate to contact with us. The following is the the picture of our moulds.

Our services:

Guangzhou Morgan Seals Co., Ltd the expert in sealing solution field who combines the rich seals research and production experience of her parent firm with the advanced technology and administration of Morgan, Worcester. Morgan Seals Research and Development ability is based on her parent firm who has won awards as scientific research achievements for more than 1000 projects and over 200 of them won scientific and technological progress prizes of municipal, provincial, ministerial and national levels. At the same time, it also has one National Certified Laboratory, one National Engineering Research Centers and three Industry Level Inspection Centers.

Contact us if you need more details on Oil Seal. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Skeleton Oil Seal、Double Lips Oil Seal. If these products fail to match your need, please contact us and we would like to provide relevant information.

Product Categories : Oil Seal

Premium Related Products

Other Products

Hot Products

Fabric Reinforced Polyester Wear Strip/RingsPolyurethane Spring Energized SealsQuality Assurance Machine Tool Soft BandsPhenolic Resin Hard Tape with Special DesignTandem Seal for Rod - Gtdi SealsSpring Energized Seal PTFE for Pump/ValveCarbon Filled PTFE Spring Energizes Seals for HydraulicVee Packing Set SealsMechanical PU Piston Seal, Piston Seal U Cup-YxdTeflon Spring Seal (PTU/ PTA/ PTB)Leading Product Hydraulic PTFE Rod SealWear Ring and Guide Tape (GST)PTFE Guide Strip Bearing Strips for Pump Guide StripPTFE+Bronze Piston Seal for Machine ToolsTeflon Spring Energized Seals for Mobile HydraulicPhenolic with Fabric Hard Tape (CG010)